STPS – our digital information board

STPS – digital communication for production

Transparency increases productivity

Since the success of Toyota’s production system in the early 1970s at the latest, transparency has been the epitome of effective production. Other concepts such as Six Sigma also focus on increasing productivity through comprehensive information. With the STPS user solution, Sinfosy GmbH is taking communication, especially in and with the shop floor, to a new level.

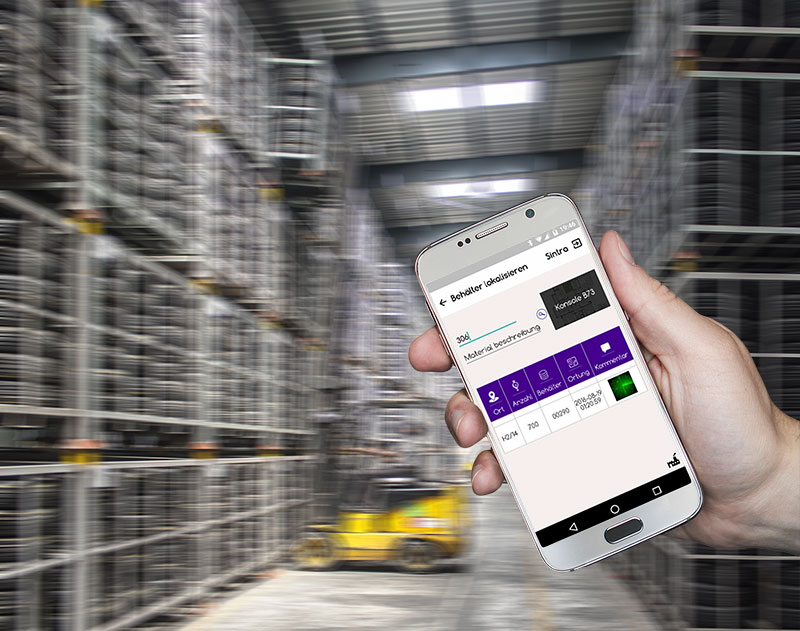

STPS brings the digital media world into the workshops. “Analogue information boards or paper boards are still very widespread in production. E-mails or documents are simply printed out and attached to the information board”, explains Dr. Karsten Königstein, Managing Director of Sinfosy GmbH. “STPS eliminates the need for paper in production.”

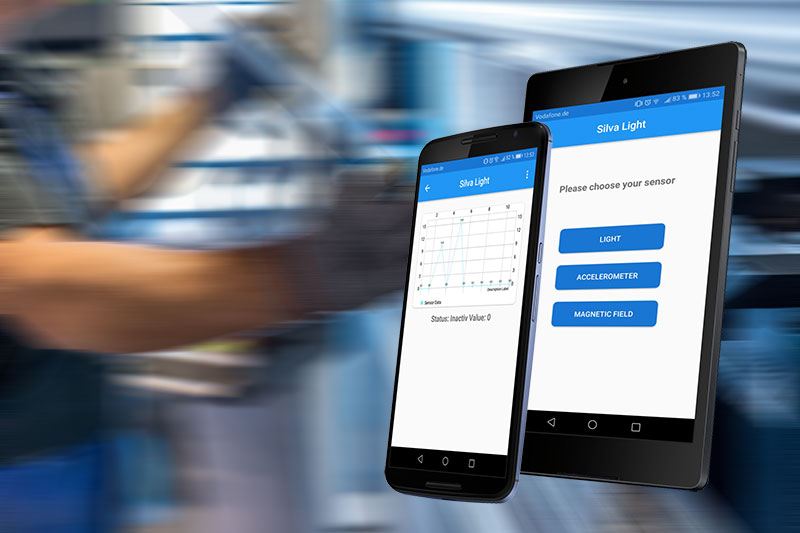

STPS provides all the data required for production on smartphones, tablets, on the PC or via monitors. The offer is extensive: Starting with the shift plan, over quality and completion data, live machine data up to a fault tracker. This also records downtimes that can be evaluated and compared with stored production specifications.

Furthermore, the integration of presentations, operating instructions as well as photos and videos is possible without any problems. Push notifications for urgent notifications, messages via chat or e-mail complete the solution. The data from SILVA light, Sinfosy’s mobile machine data acquisition system, can also be displayed. STPS is an app-based system that runs either on Android, Apple’s iOS or on the PC.

“Experience shows that up to 30 minutes are required for the exchange of information between the teams during a shift change,” explains Dr. Königstein. “This time can now be saved. With STPS, the handover only takes a few minutes or can even be completely omitted.”

STPS functions as an information node for teams or working groups. Not all information has to be accessible to all employees. By assigning rights and roles, it is possible to control exactly who is allowed to view which information.

Complex processes marked by media discontinuities are a thing of the past. The up-to-dateness of the information is guaranteed at all times. The system also makes it possible to trace when which information was available – an important criterion for quality assurance. The application is not limited to production alone. “Wherever KPI-defined processes are running, STPS is the right solution,” emphasizes Dr. Königstein.

The target groups of STPS include every manufacturing company that is committed to Smart Manufacturing and is or plans to align its production with the principles of Industry 4.0. These are primarily small and medium-sized companies that are active, for example, in the steel or metal processing industry or as automotive suppliers.

Another major advantage: STPS is a “System as a Service” solution that is implemented without having to set up a cost- and time-intensive IT project. Sinfosy provides customers with the necessary software and hardware as a service. Customers only pay a monthly fee depending on the size and number of devices used and the agreed support time (from eight hours per working day to 24/7 all-round service).

STPS was awarded the Metal Innovation Award of the State of Brandenburg in 2017.

Contact person for editors:

Evgeniia Sentsova

Teamlead Marketing

T: 03375-917 9071

M: ese@newsite.sinfosy.com

Download the press release as PDF here…